Discover the art of mug customization with sublimation! This guide walks you through the step-by-step process, from selecting the right materials to mastering the heat transfer technique, ensuring your personalized mugs are vibrant and long-lasting.

How to customize mugs with sublimation?

If you're looking to add a personal touch to your coffee mugs, sublimation is an innovative way to create unique designs that stand out. Whether it's for a thoughtful gift, a promotional item, or simply for your own enjoyment, sublimation offers a vibrant and durable result. In this guide, we’ll walk you through the sublimation process, necessary materials, a step-by-step guide, troubleshooting tips, and maintenance for your equipment.

Understanding the Sublimation Process

Sublimation is a fascinating printing process that involves converting solid dye into gas without passing through a liquid phase. This technique enables designs to become part of the material, forming a permanent bond that lasts—perfect for custom mugs.

What is Sublimation?

Sublimation is a process that utilizes heat to transfer dye onto materials. Commonly used in textiles, it’s particularly effective on polyester-coated products, including mugs. When the sublimation ink is heated, it transitions into a gas and embeds into the surface of the item, resulting in a vibrant print that won’t wash off easily. This method allows for intricate designs and full-color images to be printed with remarkable detail, making each item unique and personalized.

Moreover, sublimation is not limited to just mugs; it can be applied to a variety of substrates such as T-shirts, phone cases, and even ceramic tiles. The versatility of this process makes it a favorite among artists and businesses alike, as it allows for the creation of custom merchandise that truly stands out in the market.

The Science Behind Sublimation

At a molecular level, sublimation involves a change in state. When the sublimation printer applies heat and pressure to your design printed on sublimation paper, the solid dye transforms into a gas. This gas permeates the outer layer of the mug, cooling back into a solid and becoming part of the substrate itself. The heat causes the polymer molecules in the substrate to expand, allowing the gas to penetrate deeply, ensuring that the design is not just on the surface but integrated into the material.

This chemical bonding gives sublimated designs their durability and resistance to fading, making sublimation a popular choice for custom items. Unlike traditional printing methods, which may wear off over time, sublimated designs remain vibrant and intact even after repeated washing or exposure to sunlight. This longevity is particularly important for promotional items and gifts, where maintaining the quality of the design is essential for brand representation and customer satisfaction.

Necessary Materials for Mug Sublimation

To embark on your sublimation journey, you’ll need a few essential materials. Each component plays a crucial role in ensuring the process runs smoothly, leading to stunning results. Let’s break down what you need.

Choosing the Right Mug

Not all mugs are created equal! For sublimation, you should opt for ceramic mugs coated with a polyester layer. This coating allows for proper dye adhesion. Check for high-quality sublimation mugs from reputable suppliers for the best outcomes.

Sublimation Printer and Ink Essentials

The next critical piece of equipment is the sublimation printer and ink. While any standard printer won’t do, dedicated sublimation printers using specific inks will yield the best results. Look for printers that offer high-quality photo output since your designs often require detail and vibrant colors.

Heat Press Machine: What You Need to Know

A heat press machine is essential for mug sublimation. It needs to deliver consistent temperature and pressure evenly across the surface of the mug. There are specialized mug heat presses on the market that cater specifically to mugs, ensuring a perfect transfer every time.

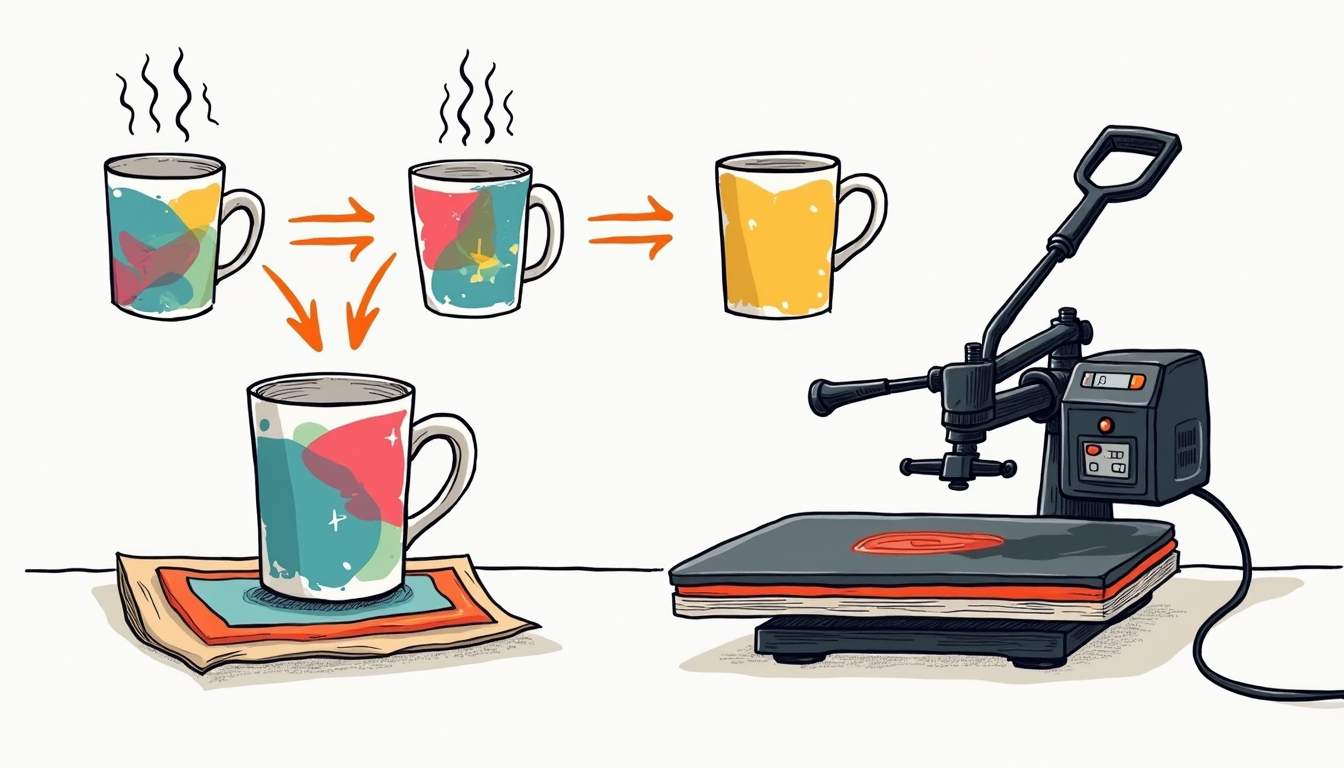

Step-by-Step Guide to Mug Sublimation

Now that you have your materials ready, let’s dive into the nitty-gritty of the sublimation process. Here’s a detailed, step-by-step guide to customize your mugs.

Preparing Your Design

First things first: you need to create a design. Software like Adobe Illustrator or CorelDRAW works well for crafting designs. Make sure your design is the correct size for the mug, usually around 8.5 x 3 inches for most standard mugs. Don’t forget to flip the image, as it will be mirrored during printing!

Printing Your Design

Load your sublimation printer with sublimation paper and ink before sending your design to print. Ensure that you select the correct paper settings for vibrant colors and clarity. Once printed, let the paper dry for a moment to avoid smudges.

Transferring the Design onto the Mug

The magic happens next! Preheat your heat press machine according to the manufacturer’s instructions. Line up the printed design on the mug using heat-resistant tape to avoid any shifting. Place the mug in the heat press and set the timer. Just wait—don’t peek! Once the time is up, carefully remove the mug and allow it to cool for a spectacular reveal!

Troubleshooting Common Sublimation Issues

Even seasoned pros encounter hiccups! Here’s how to tackle some common sublimation challenges you might face.

Dealing with Faded Prints

If your prints appear faded, it could be due to low-quality sublimation ink or inadequate heat settings. Ensure you’re using good quality inks and calibrate your heat press for optimal results. Sometimes, longer pressing times may also help.

Addressing Uneven Transfers

Uneven transfers can arise from pressure inconsistencies. Double-check that your heat press is applying even pressure and that the mug is properly positioned. Using a mug wrap might also help create uniformity in transfers.

Maintaining Your Sublimation Equipment

Finally, let’s talk about keeping your sublimation equipment in top shape! Proper maintenance extends the life of your gear and enhances the quality of your projects.

Cleaning Your Sublimation Printer

Regularly clean your sublimation printer to ensure optimal performance. Use a lint-free cloth and a small amount of cleaning solution specifically designed for printers. Follow the manufacturer’s recommendations to avoid voiding your warranty.

Properly Storing Sublimation Ink

Sublimation inks can be sensitive to temperature and light. Store them in a cool, dark place to maintain their quality. If you notice any lumps or changes in consistency, it’s time to replace them!

Taking Care of Your Heat Press Machine

Keep the heat press clean by wiping down the plates after use. Check for any wear and tear or damage on the heating elements. Regular maintenance will help sustain its longevity and efficiency.

In conclusion, customizing mugs with sublimation is an exciting and rewarding process. From understanding the science to maintaining your equipment, each step plays a vital role in producing stunning, personalized mugs that you’ll cherish for years to come. Happy sublimating!

Bring Your Custom Mug Designs to Life with Nerds

Ready to transform your unique designs into reality? At Nerds, we specialize in creating sustainable, high-quality custom mugs that are perfect for showcasing your brand or making a personal statement. With our expertise in sublimation and commitment to excellence, we ensure your logo and designs resonate with every sip. Elevate your brand or give a gift that keeps on giving. Shop Now and start your journey to memorable, bespoke merchandise with Nerds.